R

Radiant Heat: Heat communicated by radiation and transmitted by electromagnetic waves.

Radiation Area: Any part of an installation accessible to employees in which there exists a radiation level of 7.5 millirem in any one hour or over 150 millirem in any seven consecutive days.

Radiation, Direct: All radiation coming from within an x-ray tube and tube housing except the useful beam.

Radiation Hazard: Any situation where persons might be exposed to radiation in excess of the maximum permissible dose.

Radioactive Isotopes: Varieties of an element possessing the same chemical characteristics but emitting detectable radiations by means of which

they can be identified and traced.

Radioactive Material: Any compound or element which may emit any or all of the following: alpha and beta particles, electrons, photons, neutrons

and gamma and all other emissions which produce ionization directly or indirectly.

Radium: A radioactive element with the chemical symbol Ra; radium and its salts are used in gamma-ray radiography because of their radioactivity. Melting point is 700 C (1292 F).

Rapping: Knocking or jarring the pattern to loosen it from the sand in the mold before withdrawing the pattern.

Rapping Plate: A metal plate attached to a pattern to prevent injury to the pattern and assist in loosening it from the sand.

Rare Earth (RE) (Rare earth element, rare earth metal, lanthanide series, uncommon metals, Mischmetal): Any of a group of 15 similar metals

with atomic numbers 57 through 71.

Rare Gases: Helium, Argon, Neon, Krypton, Xenon and Radon.

Receiving Ladle: A ladle placed in front of the cupola into which all metal is tapped. It acts as a mixer and reservoir and to smooth out metal flow to the pouring area.

Recrystallization: A process whereby the distorted grain structure of cold-worked metals is replaced by a new, strain-free grain structure during annealing above a specific minimum temperature.

Recrystallization Temperature: The lowest temperature at which the distorted grain structure of a coldworked metal is replaced by a new, strain-free grain structure during prolonged annealing. Time, purity of the metal and prior deformation are important factors.

Reduction: The removal of oxygen or addition of hydrogen.

Reflectoscope: An instrument for the ultrasonic testing of metals.

Refractory: 1. Heat-Resistant material, usually nonmetallic, used for furnace linings, etc., 2. the quality of resisting heat.

Refractory Clay: A clay which fuses at pce 25 (1590 C, 2894 F) or higher.

Release Agent (Parting Agent): A material, as silicone, stearate, oil or wax for lubricating a die pattern or core box to facilitate easy removal of a

casting, mold or core.

Remelt: Sprues, gates, risers and defective castings returned directly to the melting pot.

Residual: 1. A trace of original material in a mold cavity after molten metal has been poured, 2. any element remaining in an alloy following melting and casting.

Residual Stress: See Stress, Residual.

Respirator: A filtering device which covers the nose and mouth and prevents inhalation of dust or fumes; should have the U.S. Bureau of Mines certificate of approval for the specific contaminant being filtered out. Handkerchiefs and gauze masks give little or no protection.

Rimmed Steel: A low-carbon steel.

Ringelmann’s Scale: In air pollution control, a black and white mesh scale reading from all clear to solid black, used to measure the density of smoke.

Observer normally used chart comparator 50 feet from the point where smoke emits.

Riser: Reservoir of molten metal from which casting feeds as it shrinks during solidification.

Riser, Blind: A riser that does not break through the top of the cope and is entirely surrounded by sand; often combined with skim gates and together

forming an efficient method of gating and feeding a casting.

Riser Distance: The length of the riser neck. The term is applied to side risers only.

Riser-Gating: Practice of running metal for the casting through the riser to help directional solidification.

Riser Height: The distance from the top of the riser when liquid to the top of the riser neck. Riser height when solid is usually several inches less than when liquid because of contraction and loss of feed metal to the casting.

Riser Neck: The connecting passage between the riser and casting. Usually only the height and width or diameter of the riser neck are reported, although the shape can be equally important.

Riser, Open: Conventional form of riser usually located at the heaviest section of the casting and extending through the entire height of the cope.

Riser Pad (Riser Contact): An enlargement of the riser neck where it joins the casting. The purpose of the pad is to prevent the riser from breaking into the casting when it is struck or cut from the casting.

Riser, Side (Side Head): A riser attached to the side of a casting.

Riser, Top (Top Head): A riser attached to the top surface of a casting.

Rodding: Reinforcing the sand in a core with metal rods or shapes to strengthen parts of the core.

Rolling Over: The operation of reversing the position of a flask. If the drag part of the pattern has been rammed with the parting surface downward, it is rolled over 18011 to allow core setting and placement of cope.

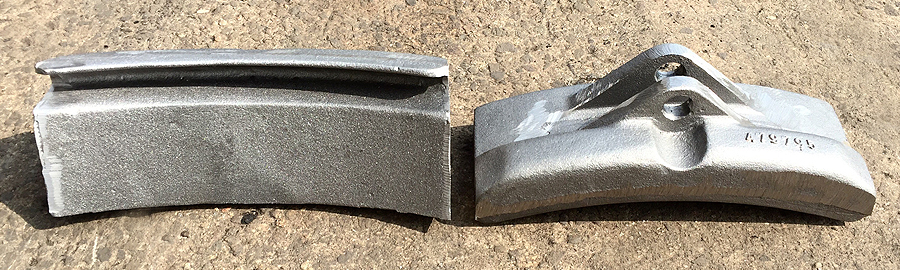

Rollover Board: A wood or metal plate on which the pattern is laid top face downward for ramming the drag half mold, the plate and half mold being turned over together before the joint is made.

Rollover Machine: A molding machine with which the flask is rolled over before the pattern is drawn from the mold.

Runner: A channel through which molten metal or slag is passed from one receptacle ‘ to another; in a mold, the portion of the gate assembly that connects the downgate or s ‘ sprue with the casting ingate or riser. The term also applies to similar portions of master patterns, pattern die, patterns,

investment mold and finished casting.

Runner Extension: In a mold, that part of a runner which extends beyond the farthest ingate as a blind end. It acts as a dirt trap since the first rush of metal along the runner will pick up any loose particles of sand or dirt and carry them into the extension and not into the mold cavity.

Runner Riser: A conventional runner, usually in the horizontal plane, which permits flow of molten metal to the ingate and is large enough to act as a reservoir to feed the casting.

Runout: 1. A casting defect caused by incomplete filling of the mold due to molten metal draining or leaking out of some part of the mold cavity during

pouring; escape of molten metal from a furnace, mold or melting crucible, 2. the actual piece of metal that “runs out” of the mold.