F

Facing Sand: Specially prepared molding sand mixture used in the mold adjacent to the pattern to produce a smooth casting surface.

Fatigue Crack or Failure: A fracture starting from a nucleus where there is an abnormal concentration of cyclic stress and propagating through the metal.

The fracture surface is smooth and frequently shows concentric (sea shell) markings with a nucleus as a center.

Fatigue Limit: Maximum stress that a metal will withstand without failure for a specified large number of cycles of stress. Usually synonymous with

Endurance Limit.

Feeding: Pouring additional molten metal into a freshly poured mold to compensate for volume shrinkage while the casting is solidifying; the continuous

supply of molten metal, as from a riser, to the solidifying metal in the casting; keeping risers open by manipulation of feeding rods,

Ferritic Steels: Steels in which ferrite is the predominant phase. These steels are magnetic.

Fettle: British term meaning the process of removing all runners and risers and cleaning off adhering sand from the casting. Also refers to the removal

of slag from the inside of the cupola and in Britain to repair the bed of an open hearth.

Finish Mark: A symbol (f, fl, f2, etc.) appearing on the line of a drawing that represents the edge of the surface of the casting to be machined or

otherwise finished.

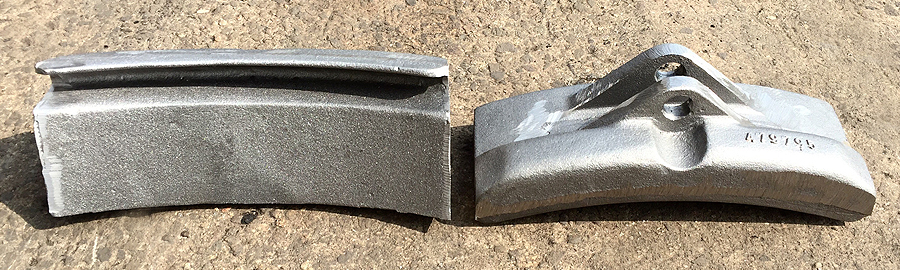

Flash: A thin section of metal formed at the mold, core or die joint or parting in a casting due to the cope and drag not matching completely or where core

and coreprint do not match.

Flask Bar: A reinforcing member attached within either half of a flask to help hold the rammed sand in position.

Flask Clamp: A device for binding together the parts of a flask.

Flat Back: A pattern with a flat surface at the joint of the mold. It lies wholly within the drag and the joint of the cope is a plane surface.

Flow-Off (Pop-Off): A large vent, usually located at the high point of the mold cavity. In addition to letting air and mold gases escape as metal fills the

mold cavity, the flow-off fills with metal and acts to relieve the surge of pressure near the end of the pouring.