Architectural Restoration

With careful precision and artistic creativity we have the ability to render architectural and historical castings. Using prints, sketches, 3D scans, or even original pieces we have reproduced historical castings such as entire fence segments including decorative florets, bases, post and finials. We have also reproduced bells, yokes, loom, fireplace, stove, cider presses parts, or anything you can think of up to 1300 lbs.

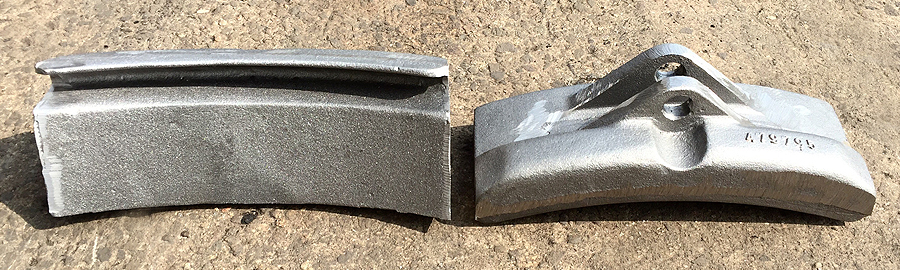

Reproduction from Original

The process takes an original part, which in many cases we have to repair or reconstruct sections to use as a pattern. From that repaired part we will reproduce an exact replica. In many cases the historian will request that a historical blemish be left in tact to better exemplify the original.

3D Scanning

This process uses laser scanning to very accurately measures the surface area of an existing part. This 3D data is either exported to a print or loaded directly into a CNC milling machine program and our pattern maker will program this piece of equipment to cut from wood, foam or acrylic a detailed part. From that pattern a new casting or in many cases multiple castings can be produced.

Rubber Mold Technique

In this process the pattern maker will repair the blemishes on the original casting use the repaired original casting to produce a negative rubber or poly mold. From that negative a new positive acrylic positive pattern can be made and lasting the sand mold produced from the acrylic pattern, which will ultimately produce the iron castings.